2019 PVA Delta 8 - 4 Axis Robotic Dispensing Machine for Adhesives Sealants & Conformal Coatings

2019 PVA Delta 8 - 4 Axis Robotic Dispensing Machine for Adhesives Sealants & Conformal Coatings

$24,950 (USD)

Location:Central Falls, RI

Description

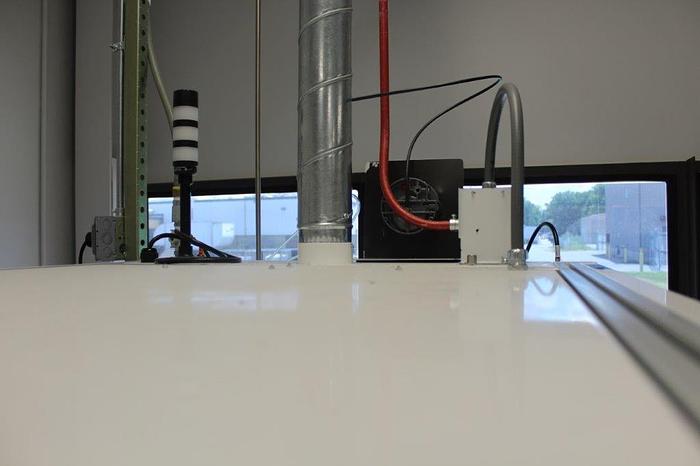

This is a 2019 PVA Delta 8 Four Axis Robotic Dispensing Machine for Adhesives Sealants & Conformal Coatings... in perfect condition!

Equipped with the following options...

- D8 4 AXIS

- 10 Gallon Tank Assembly

- Delta 8 Servo 4th Axis with 3 Dispense Stations and 2 Position Tilts

- Pin Chain Conveyor with Hand Crank

- Gige Camera Assembly

- Blacklight LED Strip

- and much more!

PVA was founded in 1992 by president Anthony Hynes. Hynes began selling dispensing valves for automated and manual dispensing applications out of his home prior to moving to Rensselaer Polytechnic Institute's (RPI) later that year. It was there that PVA began building XYZ robots to automate their growing valve technology. PVA's dispensing valve product line grew rapidly to include technology that proved superior for accurately applying conformal coating materials. In 1994, PVA debuted a selective conformal coating system that would later become the PVA2000. The PVA2000 improved on existing XYZ plotting systems by introducing a closed-loop servo controlled process that proved increasingly accurate and rugged.

PVA quickly began to claim local and national accolades by winning the 1995 National Incubator Tenant of the Year and the Capital District Business Review's Small Business of the year in 1998. PVA claimed SMT Magazine's Vision Award for innovative valve technology and Circuits Assembly's prestigious Service Excellence Award for three consecutive years.

PVA is now headquartered in a 135,000 square foot facility in Cohoes, New York with regional sites stationed throughout North America, Europe, and Asia. PVA continues to bring our customers the finest quality in automated and manual dispensing solutions while servicing over 6,000 modules at many of the world's largest manufacturers.

PVA continues to be owned and operated by founder Anthony Hynes.

Each PVA robot is delivered with our proprietary Windows®-based programming software, PathMaster®. PathMaster is an intuitive point and click interface that allows programmers of various technical backgrounds to easily create paths of motion in minutes. PathMaster features numerous programming tools that are specifically tailored to coating and dispensing processes. Area fill functions, cut and paste array patterns, and line by line editing are but a few of the features you will enjoy.

PathMaster also comes with a free offline programming package that allows you to create motion at your desktop. Import CAD drawings to create bead or dot programs or utilize FastPath™ to quickly teach coating programs via digital images.

• PathMaster® CD with offline programming package

At PVA we pride ourselves on providing every business partner with exceptional post sale support. Circuits Assembly magazine has recognized our commitment to this aim by awarding PVA with the prestigious Service Excellence Award in three consecutive years. PVA’s support infrastructure is second to none in the industry with regional centers stationed throughout North America, Europe, and providing immediate local response.

The Delta 8 is a compact three or four-axis robotic platform for dispensing a wide variety of adhesives, sealants, and conformal coatings.

The Delta 8 employs a robust gantry system featuring precision ball screw slides driven by brushless DC servo motors. Every axis of motion features optical encoder feedback for a truly closed-loop process.

Specifications (Single Head)

X-Axis Stroke 621 mm (24.45”)

Y-Axis Stroke 595 mm (23.43”)

Z-Axis Stroke 100 mm (3.94”)

Repeatability 0.025 mm (0.001”)

Facilities

Power 120V-220V +/-10%, 50-60 Hz

Air 80 psi, dry unlubricated

Exhaust 300 cfm (coating applications only)

PART NUMBER

DESCRIPTION

Delta 8

Delta 8 Coating / Dispensing System- Fully enclosed work area with hatch service door and safety interlock

- Onboard PC with flat screen monitor and PVA Portal

PVA-BL

Black Light Mounted in Robot

PVA-VISION

XY Fiducial Correction Camera

PVA-BC-H

Handheld Barcode Reader

DATA-LOG

Data Logging - Barcode info, date and time, cycle time

A programmable fourth axis option permits rotation of the dispense head in a 350 degree motion. With this option, an application valve can tilt at an adjustable angle and rotate. This is critical in instances where coating must be applied on all sides or underneath a component. This is an upgrade over more common single or dual tilt capabilities as these can only approach one or two sides of a component respectively. This is a fully controllable axis of motion with coordinated travel and acceleration and deceleration on the fly.

DESCRIPTION

PVA-4X Optional Fourth Axis Upgrade

- Includes (3) Dispense Stations and (2) Two Position Tilts

PVA robots can offer a variety of valve mount configurations to customize your process. Utilizing the robot’s high payload capacity, multiple valves can be installed on the motion platform to process multiple assemblies simultaneously, apply multiple materials, or use multiple application heads to achieve the desired process results.

Valve Application Type

Suitable Coatings Pattern

Pattern Width

FCS300-ES

Atomized spray All coating types Circular

0.125” – 0.5”

FC100-C

Non-atomized Solvent-based Film

0.25” – 0.5”

FCM100

Micro propulsion All coating types Bead, dot

0.010” min

FC100-MC

Bead, dot

All coating types Bead, dot

0.010” min

FCS300

Atomized spray All coating types Circular / fan

0.25” – 2”+

FCS300-ES-M

FCS300-ES Atomized Spray Valve Mount

- Extended spray cap (0.125" - 0.50")

- Using Dow 1-2577

FCS300-R-M

FCS300 Atomized Spray Valve

- Using Dow 1-2577

FC100-MC-M

FC100-MC Front Closing Valve Mount

- Using Dow 1-2577

SJ100-M

Selective Conformal Coating Jet Mount

Material tanks are available in two and ten-gallon sizes. Two gallon flip-top tanks contain an oval opening that requires material to be poured into the reservoir. Two and ten gallon top-ported pressure vessels have an open top that permit an entire material bucket to be dropped into the container. Alternatively, disposable plastic liners are available for these tanks and allow for quick cleaning in applications that warrant pouring of material. Two liter tanks allow an entire bottle to be placed into the reservoir so clean up is minimal.

PVA-2GL

2 Gallon Top-Ported Material Reservoir

PVA-10G

10 Gallon Top-Ported Material Reservoir

PVA-OP-11-S

Digital Scale Low Level Material Sensor

PVA Robots can be outfitted with either a silicone edge belt or edge chain conveyor for transport of assemblies in and out of the work area. Both conveyor options require the SMEMA standard 4.75 mm (0.187”) clearance on sides to be transported on the conveyor. The edge belt conveyor can carry assemblies weighing up to 2.3 kg (5 lbs). Edge chain conveyors have a maximum transport weight of 4.5 kg (10 lbs). Conveyors are 34” long through the cell and can accommodate a maximum 18” wide pallet. Conveyor speeds are adjustable Up to 406 mm/sec (16 in/sec). All PVA conveyors can offer bi-directional motion right to left or left to right. SMEMA communication protocol is included. Each conveyor has three-part in place sensors, one on the inbound, one in process, and one outbound. A single pneumatic stop is used to locate assemblies in the work area.

CONVEYOR-3Z

66" Three Zone Pin Chain Conveyor Through Delta 8

- Inlet, process, outlet zones

PVA-CRANK

Hand Crank Adjust

PVA-AUTO

Automatic Rail Adjust

PVA offers a kit of common spare parts for each robot in a standard package. This kit includes valve seals and needles, relays, cable assemblies, a brushless motor, and fuses. For a comprehensive list of components, please ask your PVA sales representative. A comprehensive, customized machine spare parts list will follow with your operating manual and will include all pertinent options selected for your process.

# LCCA-000000-101724-A

Picture# 061824

* All information deemed accurate but may vary from model to model.

Contact Larry for any questions you may have... GOOGLE "Larry Razza Machinery"

Contact us at Four Zero One - Nine Six Five - Five Five Five Seven

___________________________________________________

Equipment Financing Available, please contact us!

Fast Application, it’s all filled in for you...

Online leasing applications (get LOW monthly payments)

* Please Note: Not all machines may qualify for Leasing.

Payments: We accept all Major Credit Cards, Bank Wires, Company and Personal Checks.

SHIPPING: Contact us for great rates on shipping...

We always get better rates...

Please email us for a rigging and shipping quote; just include the zip code when inquiring and if you have a loading dock or ground level with forklift. Thank you!

Contact us at Four Zero One - Nine Six Five - Five Five Five Seven

We also ship worldwide.

CONDITIONS: All quotations are for immediate acceptance. They are subject to withdrawal, change and prior sale without notice. Shipping dates are only approximate and contingent upon delays beyond our control. All orders received are binding only when they have been accepted and acknowledged by us in writing. Provisions in customer’s purchase orders contrary to these conditions shall not be binding upon us unless accepted in writing. Unless otherwise specified, prices quoted are F.O.B. shipping point, exclusive of State, County and Federal taxes which must be added where applicable. Insurance on shipment must be requested by email, there will be an additional charge for shipping insurance. Shipping destination must be available to receive the shipment… any costs incurred on delays due to the buyers’ destination being unable to receive the shipment and/or additional services required, will be the responsibility of the buyer. Care is taken to give reliable specifications, but these are not guaranteed. We reserve the right to correct typographical errors. All used equipment is sold "as is".

INDEMNIFICATION: Used Machines may not incorporate approved activating mechanisms, operator safety devices or safety guards as required by OSHA or otherwise. It is the user's responsibility that the said machines be so equipped and safeguarded to meet OSHA and any other requirements before placing such machinery into operation. User agrees to indemnify and hold Seller harmless of and from any and all claims or liabilities from accidents involving these machines caused by failure of user, his employees, or agent to follow instructions, warnings, or recommendations furnished by manufacturer, or Seller, or by failure of user to comply with Federal, State and Local laws applicable to such equipment including the Occupational Safety and Health Act of 1970. User shall notify Seller promptly after occurrence of any accident involving these machines, and shall cooperate fully with Seller. or Seller's agent in investigating and determining the cause of said accident.

Specifications

| Manufacturer | PVA |

| Model | Delta 8 |

| Year | 2019 |

| Condition | Used |

| Stock Number | LCCA-000000-101724-A |