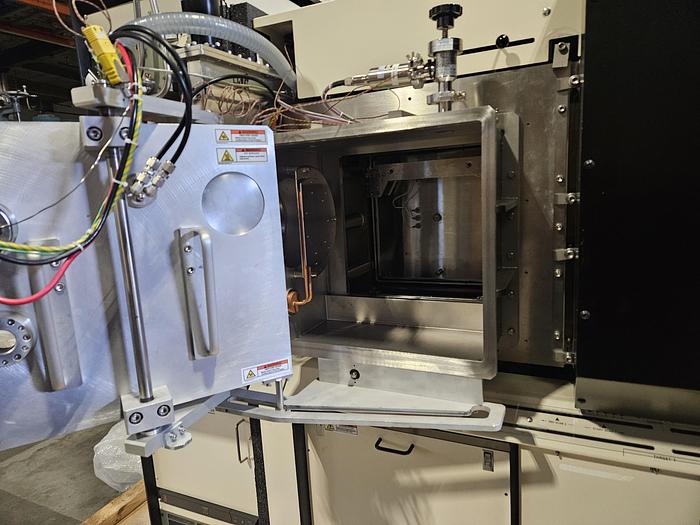

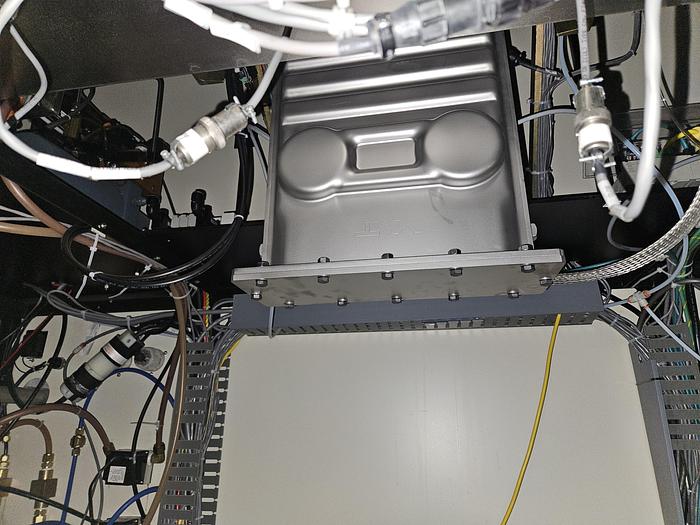

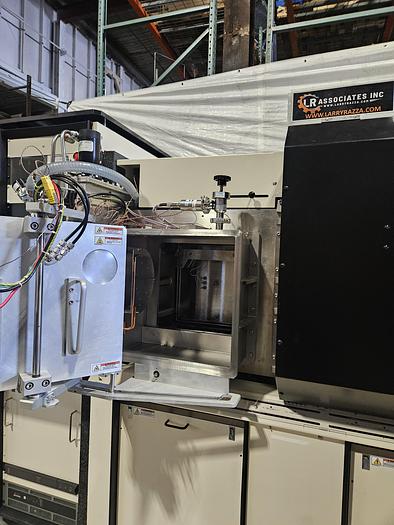

KDF 654i Sputtering Machine batch systems dual load lock in-line RF / DC side Vacuum Metallizing

KDF 654i Sputtering Machine batch systems dual load lock in-line RF / DC side Vacuum Metallizing

$179,000 (USD)

Location:Central Falls, RI

Description

This is a KDF 654i sputtering machine batch systems dual load lock in-line RF / DC side... in excellent running condition!

654i

Developed for the rapidly growing telecommunications and compound semiconductor markets, the four-target versatility of 654i tools can be applied to full range of leading edge microelectronic component manufacturing applications. The system provides enhanced etch and deposition uniformity and high-speed batch processing. ... see additional information on PDF below.

The 600i Series systems are particularly popular for sensitive applications requiring target material that produces unusually high particulate contamination.

The 600i Series includes the 603i, 643i, 654i, and 654ix. The ix series systems offer an extended sputter area to increase process uniformity utilizing KDF’s “X-series”™ cathodes. The ix series also supports KDF’s new LMM™ cathode along with other cathodes.

Both the 654i and the 654ix offer four-target versatility. All 600i series systems can also be enhanced with scan velocity profiling. The 600i series systems all meet the Semiconductor S2-0706 safety spec as part of the standard system package, a CE option for the European community is available. Pulsed DC sputtering via Advanced Energy Pinnacle Plus is also available.

All 600i series system have remote PC accessibility allowing for software upgrades & file repair via an Internet Ethernet connection. Full documentation is standard and is available on std. paper, clean room paper or an electronic CD version. For those applications that require an extra level of cleanliness or handling the Robotic option is available.

In line with your process

The most reliable in-line sputtering tools in the industry are developed and manufactured by KDF. All of KDF’s systems are engineered to meet versatility and high throughput demands across a number of markets at the industry’s lowest cost of ownership.

- Mainstream silicon

- Emerging materials

- Flat panel displays

- Optical communications

- Medical devices

Across all platforms, KDF’s in-line batch sputtering systems are easier to use and maintain than cluster tools. KDF’s solutions provide users with increased:

- Film uniformity

- Throughput run to run

- Process stability

- ROI

- Automation

- Tool uptime

- Reliability

- Environmental health and safety benefits

KDF meets the needs of its customers by quickly developing tailored solutions and building on its core competencies. KDF can specifically engineer its tools for increased throughput, ROI or time to market. All existing KDF equipment is supported with upgrades and retrofits. In addition, as the OEM for MRC batch systems, KDF sustains all MRC batch products offering complete parts and service support on a world wide basis.

600i Series

603i, 643i, 643ix, 654i and 654ix

The 600i Series is targeted towards sensitive applications using both standard materials and those that produce particulate contamination. The tools in this family surpass the criteria for deposition of thin films in high-density devices and other applications requiring absolutely minimal defects.

- Vertical side sputtering systems

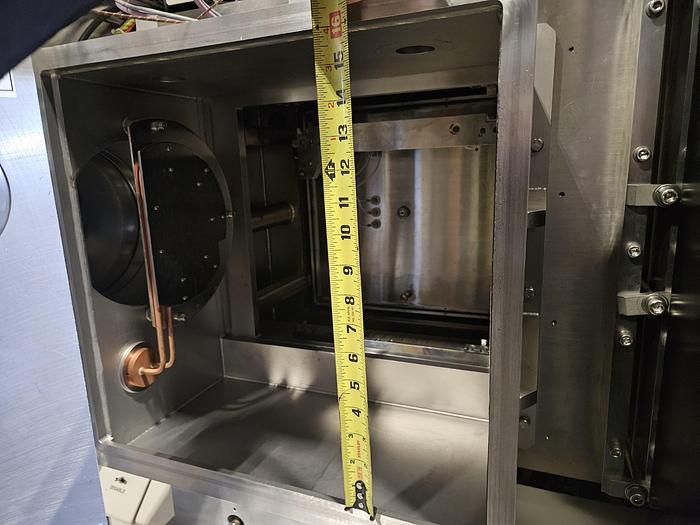

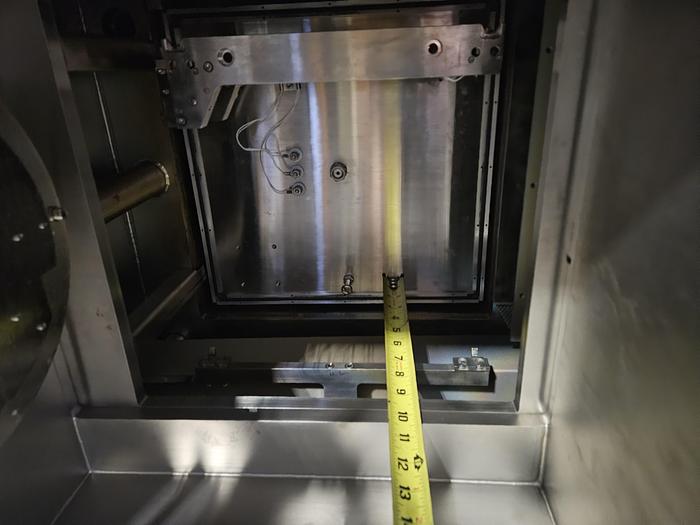

- 13” x 13” pallet size

- Small footprint

- Dual-process loadlock

- Optional OPUS Robot designed for particulate-free, reliable cassette to cassette substrate handling operations

- Multiple bias types enable denser films and planarization

- Multi-size capability enables rapid change from one substrate to another; substrate size can be changed run to run (pallet based)

- Optional integrated RGA for process and fault monitoring of gas peaks along with integrated hivac step

- New in situ pallet optical measurement hardware with integrated software allowing operators to program and control actual pallet temperature

The 600i Series features multi-process sputtering for increased process flexibility and higher throughput. The 600ix Series family also features a special application Linear Moving Magnetron™ Cathode. The patented design of the LMM™ Cathode is engineered for efficiency in today’s most demanding applications by providing bulletproof high-rate reactive process, full face erosion and low particle generation. In addition, the 600i Series can handle one 8” wafer and as many as thirty-six 2” wafers. Optional gas delivery systems allow for enhanced reactive processes.

600i Series Vacuum Specifications

- Chamber ultimate ≤1 x 10-7 torr

- Chamber leak rate, 20 minutes to 1 x 10-4 torr

- High vacuum dome ultimate ≤1 x 10-7 torr.

- High vacuum dome leak rate, 15 minutes to 1 x 10-4 torr

- Pump down from atmosphere 110 minutes or less to 1 x 10-6 torr or 2 x 10-7 torr overnight.

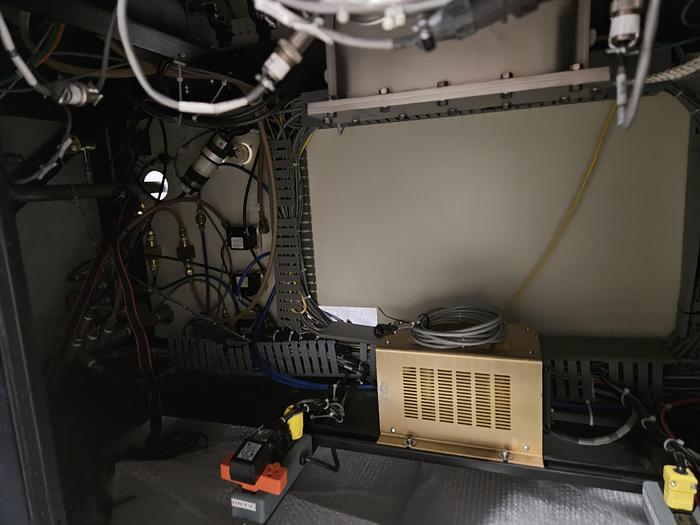

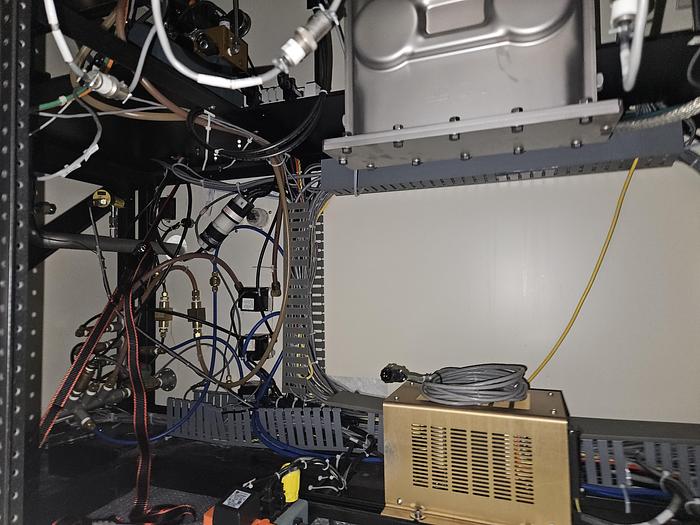

600i Series System Hardware Features

- 12kW low stored energy DC power supplies (Advanced Energy). Optional Pinnacle Plus power supplies.

- Integrated throttling SS VAT valve allowing for upstream or downstream pressure control.

- MKS multi component “Smart” 390 and 925 gauges for integrated vacuum measurements

- Process gas control with up to four gas controllers; feedback controlled capacitance manometer; master/slave gas select ability; and gas ratio control.

- Stepper motor pallet carrier drive with optical encoder providing accurate programmable pallet carrier positioning, scan velocity profiling available

- Low pressure hydraulics system for safety and smooth operation.

- Loadlock linear sensor – computer controller positioning system for increased loadlock accuracy and more limited fail-safe.

- Optional 1.25 or 3.0 kW RF solid state power supply (Advanced Energ

- Complies with NFPA79 guidelines

- Consult factory for an extensive list of standard options.

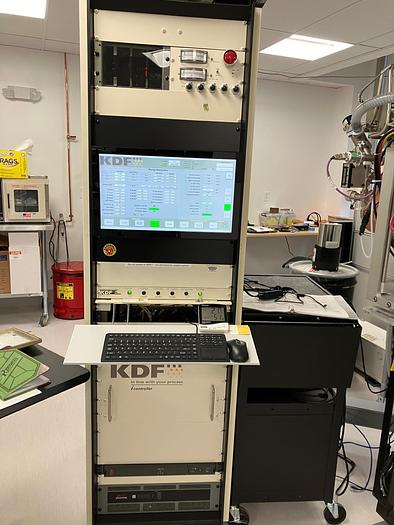

600i Series Computer Sub-System

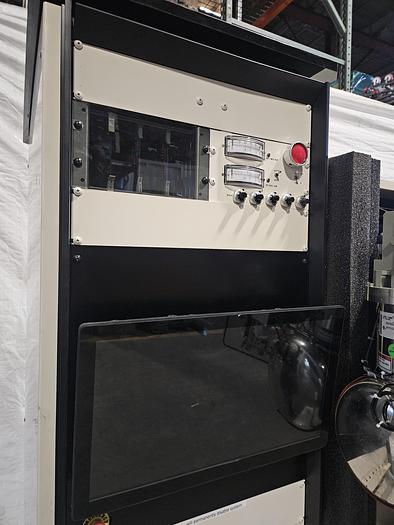

- Windows™ 10 based real-time GUI environment, coupled with 24” LCD touchscreen monitor mounted on an umbilicaled mobile HI cart.

- Context sensitive recipe manger running out of Microsoft® SQL database

- Fully integrated package for real-time data display, data logging fully compatible with Excel™, Lotus™ and other Windows™ applications, report generation, remote interface and printing

- Optional connectivity to SECS/GEM communication and Windows™ applications through and OPC server interface.

- Distributed Rockwell Control System utilizing Device Net and Ethernet IP field bus technologies

- Maintenance test suite with full diagnostic and manual process control capability

- Service friendly fully enclosed electronic cabinet

600i Series Basic Facility Requirements

- Power: 208 VAC, 3-phase, 100 Amps.

- Water: 6.5 GPM, 70 PSIG min., 10°C - 24°C

- Compressed Air: 85 - 100 PSIG.

- Process Gas: 25 PSIG 99.999%.

- Pure Gas: Dry N2

Operating Range

1. DC kW servo .5 – 10kW *.

2. RF kW servo 0.1 – 1.2kW **.

3. RF kV servo .10 ‐ 2.5kV **.

4. RF Etch 0.2kW – 1.25kW, 0.2kV – 1.5kV **.

5. Gas 1 Argon flow 10 ‐ 500 SCCM.

6. Gas 2 Nitrogen flow 5 ‐ 100 SCCM.

7. Minimum sputtering pressure 3 millitorr, maximum pressure 25 millitorr

8. Gas burst range to 50 millitorr

9. Chamber Heat .2 ‐ 3.0kW.

10. Load lock Heat 10 ‐ 21 amps.

11. Pallet carrier scan speed 2 ‐ 800cpm.

12. Pallet carrier scan passes 1 –1500. w/scan dwell

* Power level is target dependent

** External (kV) Mode Option ‐ Actual kV feedback depends on target power and

impedance.

RF generator servo modes Load Power, Forward Power and External (kV).

654 Series System

654i

Basic 654i System

Rev. G, 1/18

KDF 654i Part Number KDF06501

1. Rockwell Automation programmable controller and KDF compact PC with

Windows 10 for application graphics displayed on 24” flat panel touch screen.

2. Software downloads and remote system diagnostics available through Webex or

GoToMyPC internet connections.

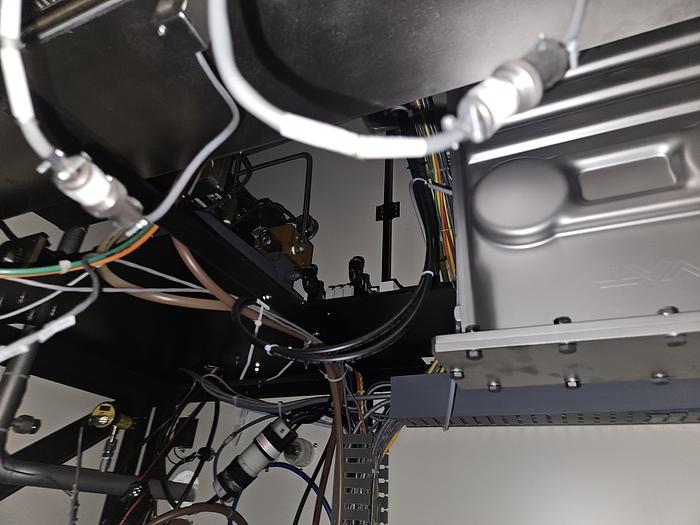

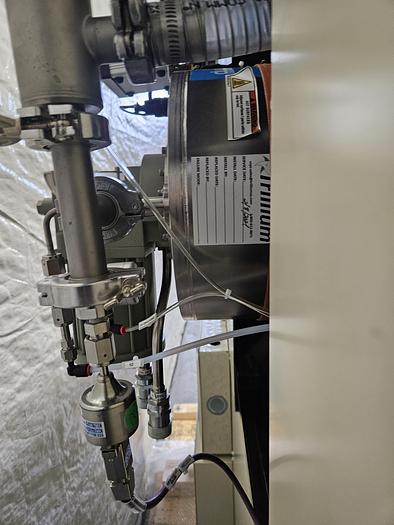

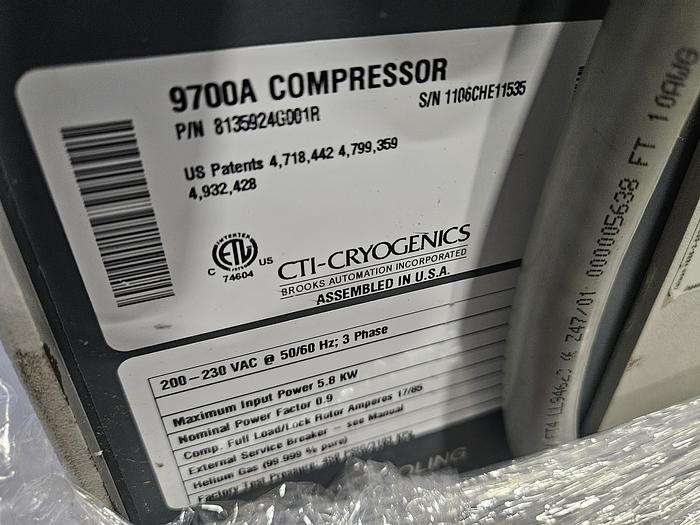

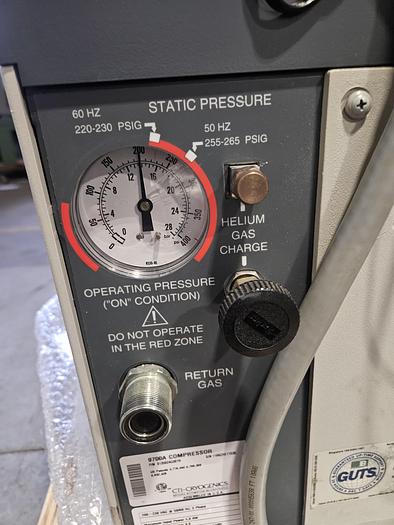

3. CTI Cryo‐Torr High Vacuum Pumps w/10 ft lines.

4. Chamber CTI‐10, Load lock CTI–8F cryo pumps with integrated KDF diode

readouts, 9700A Compressor, HVA load lock gate valve and load lock heat lamp

assembly.

5. Four RF/DC Planar Magnetron Cathodes.

6. KDF (DC only) Switching Network for target selection.

7. MKS Mass Flow Controller “G” series (MFC) for process and reactive gases. Argon

500sccm.

8. VAT throttling gate valve and GP 390 and MKS 925 gauges.

9. Advanced Energy Passive, Low‐Z, 12KW, Pinnacle DC Power Supply.

10. Three software selectable servo modes; Voltage, Current and Power.

11. Stainless steel rough lines with KF 40 fittings.

12. Stainless steel, electro polished, no bend, ¼ inch gas lines with VCR connections.

13. Applied Motion Controller, Stepper motor and Encoder assembly for accurate

pallet carrier speed control and positioning.

14. Movable shutters.

15. Low‐pressure hydraulic seal plate motion.

16. Multi‐level password interlocked motion and vacuum controls.

17. Maintenance utility features including auto cryo regeneration, chamber and

Loadlock pump/vent, ion tube degas and leak backs.

18. Upstream and downstream process gas servo modes are software

programmable. Both servo modes are capable of “Pressure” gas control type and

burst trigger ignition.

19. (2) SS flat pallets pinned to customer’s wafer size

20. Semi S2‐0310A Compliant

Vacuum Specifications

1. Chamber Base Pressure 1.0 x 10‐7 torr.

2. Chamber Leak Rate 20 minutes to 1.0 x 10‐4

3. Chamber Pump Down 110 minutes to 1.0 x 10‐6

4. Load Lock base pressure 1.0 x 10‐7

5. Leak Rate 15 minutes to 1.0 x 10‐4

Upgrades on this machine:

1. 654ix

Replaces standard (4) target 5 x 15 cathode system with system designed for (4) 5x17 “X Series”™

cathodes ‐ KDF Part # KDF06501X

2. RF Option.

Adds RF capability for etching and target sputtering. Option includes Advanced Energy 1.2 KW

power supply with water cooled switching network and flex lines – KDF Part # KDF06

3. Second / Third / Fourth gas inlet

The customer to specify flow range and gas type ‐ KDF Part # KDF06003 QTY (2)

4. Pfeiffer L 100 dry pump.

Dry pump recommended for any oxygenated process. 58 CFM ‐ KDF Part # K402‐076

5. Mark II Planar Cathode Dielectric materials) ‐ Part # KCA0037 QTY (2)

Cathode Dimensions: 5”x17”

6. NTX UPSILON Inset Cathode™ ‐ Part # KCA0028

Cathode Dimensions: 5”x17”.

7. Delete NTX RF/DC Planar Magnetron – Part # KDF06588 QTY (3)

Other options:

Upgrade RF 1.2kw power to 3kw AE RFX supply

Install Heat over Etch capability (retrofit)

Supply (2) custom pallets per customer substrate size

Spare Backing plate, KCA0022 (2)

Spare shield kit, K6A0135

PTWS # LTW-0000-010925-A

Picture# file KDF

* All information deemed accurate but may vary from model to model.

Contact Larry for any questions please call Four Zero One - Nine Six Five - Five Five Five Seven

___________________________________________________

Equipment Financing Available, please contact us!

Fast Application, it’s all filled in for you...

Online leasing applications (get LOW monthly payments)

* Please Note: Not all machines may qualify for Leasing.

Payments: We accept all Major Credit Cards, Bank Wires, Company and Personal Checks.

SHIPPING: Contact us for great rates on shipping...

We always get better rates...

Please email us for a rigging and shipping quote; just include the zip code when inquiring and if you have a loading dock or ground level with forklift. Thank you!

Contact us at Four Zero One - Nine Six Five - Five Five Five Seven

We also ship worldwide.

CONDITIONS: All quotations are for immediate acceptance. They are subject to withdrawal, change and prior sale without notice. Shipping dates are only approximate and contingent upon delays beyond our control. All orders received are binding only when they have been accepted and acknowledged by us in writing. Provisions in customer’s purchase orders contrary to these conditions shall not be binding upon us unless accepted in writing. Unless otherwise specified, prices quoted are F.O.B. shipping point, exclusive of State, County and Federal taxes which must be added where applicable. Insurance on shipment must be requested by email, there will be an additional charge for shipping insurance. Shipping destination must be available to receive the shipment… any costs incurred on delays due to the buyers’ destination being unable to receive the shipment and/or additional services required, will be the responsibility of the buyer. Care is taken to give reliable specifications, but these are not guaranteed. We reserve the right to correct typographical errors. All used equipment is sold "as is".

INDEMNIFICATION: Used Machines may not incorporate approved activating mechanisms, operator safety devices or safety guards as required by OSHA or otherwise. It is the user's responsibility that the said machines be so equipped and safeguarded to meet OSHA and any other requirements before placing such machinery into operation. User agrees to indemnify and hold Seller harmless of and from any and all claims or liabilities from accidents involving these machines caused by failure of user, his employees, or agent to follow instructions, warnings, or recommendations furnished by manufacturer, or Seller, or by failure of user to comply with Federal, State and Local laws applicable to such equipment including the Occupational Safety and Health Act of 1970. User shall notify Seller promptly after occurrence of any accident involving these machines and shall cooperate fully with Seller. or Seller's agent in investigating and determining the cause of said accident

Specifications

| Manufacturer | KDF Electronics |

| Model | 654i |

| Year | 2021 |

| Condition | Used |

| Serial Number | Part Number KDF06501 |

| Stock Number | LTW-0000-010925-A |