2022 Turnkey Egyptian Syrian Bread Making System Oven, Flatteners, Dividers, Proofers, and Conveyors... Complete Bread Making System! Has No Hours On It!!! Basically It's New!

2022 Turnkey Egyptian Syrian Bread Making System Oven, Flatteners, Dividers, Proofers, and Conveyors... Complete Bread Making System! Has No Hours On It!!! Basically It's New!

Contact us for price

Location:Attleboro, MA

Description

This is a 2022 Turnkey Egyptian Syrian Bread Making System Oven, Flatteners, Dividers, Proofers, and Conveyors... Complete Bread Making System!

This Unit Has No Hours On It!!! ...Basically It's New!

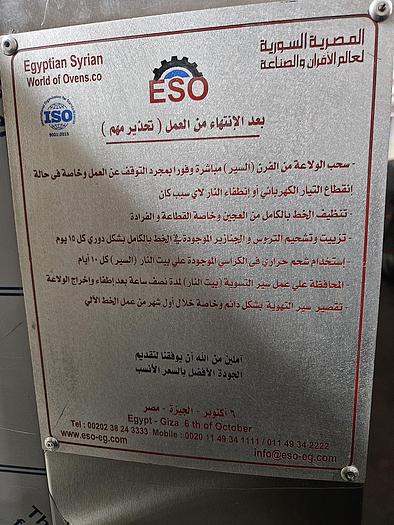

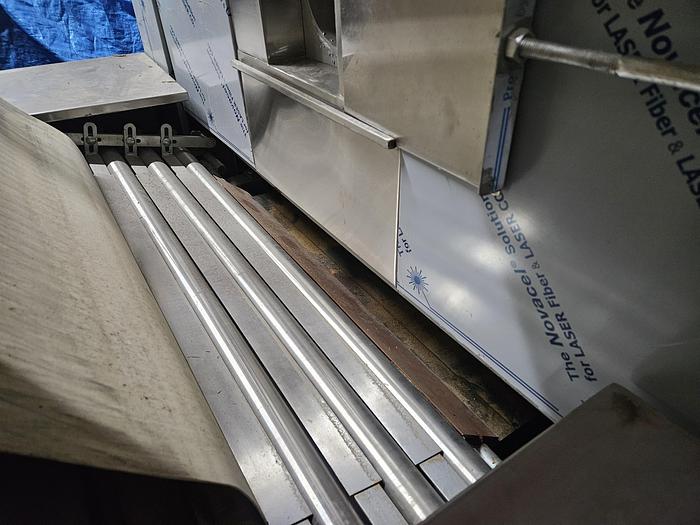

Tunnel Oven

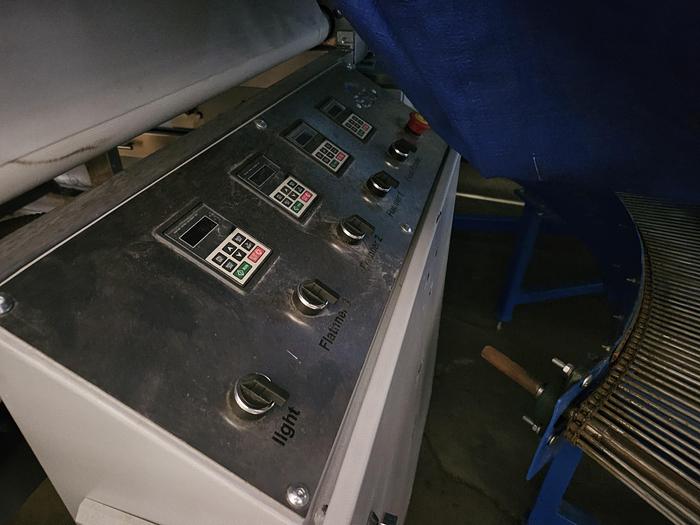

Length /525/cm, width /185/cm, height/165 /cm. The External cover is made from Stainless Steel. The Insulation: the oven has a good insulating with a thickness of /40/cm from both sides and minimize the heat transmission to outside. the thickness of house of fire is 22 CM to reduce using fuel consumption power saving Equipped with /70/cm iron conveyor equipped with tracks to reduce noise. The Tunnel is made of high-quality Stones which prepared to bear high temperature /1000/degree The burner is not included (according to the Canadian and American rules for safety and health). Equipped with /3 / HP motor Equipped with control panel with speed control and Electric flame

Automatic Flattener

Equipped with easy and advanced adjustment mechanism. A - First Flattener Phase: ( Two phases ) The dough gets pressed by a cylinder coated with alimentary Felt fabric. The cylinder is equipped with flour spray. Then the dough keeps moving on felt conveyor until it reaches 2 cylinders coated with Hard Chrome. then the dough moves to a conveyor made of polyester and then the dough reach to the Final Flattener Phase. The conveyor width is /40/ cm. Equipped with control panel and on - off button. The work on 1 motor – 1HP The dough moves from first phase to final phase by Pneumatic System (Air Pressure) and light sensor (photocell).

Final Flattener Phase Consists of /2/ cylinders which coated with Hard Chrome. the cylinders width is /70/cm the dough moves through them to reach the final flattener Proofer. The Divider equipped with control panel with on, off button The Divider equipped with Inverter to control the speed. Work on 1 Motor – 1.5Hp The Divider equipped with safety sensors on the cylinders and flour spray and the control panel will control the first dividing proofer.

First Dividing Proofer

The Proofer length is /500/cm, width is /40/cm Consists of /5/ layers of felt fabric conveyor The proofer is equipped with Aluminum doors installed on Aluminum rail top to assure the good quality of proofer. The proofer equipped with one motor 1 / HP.x

Final Flattener Proofer

It contains /15/ layers of felt fabric. The length /600/cm, width of screen /70/cm Equipped with /3/ HP motor. The Final proofer equipped with control panel with on, off button The proofer is equipped with Aluminum doors installed on Aluminum rail top to assure the good quality of proofer.

Automatic Dough Divider

Works according to the Pneumatic System (Air Pressure) Equipped with light sensors (photocell). Equipped with /75/Kgs alimentary Stainless-Steel Tank (Bucket). The Lower Tank (Bucket) is made of Stainless steel (alimentary). Stainless steel knife to push down the dough to the spirals The Spirals made of Teflon (plastic) and equipped with 1 Motor – 1HP The knife equipped with a 1Motor – 0.5HP. Equipped with (2) Stainless Steel Blades to cut the dough. The dough moves on a felt fabric conveyor belt 30cm width. The dough gets pressed by cylinder coated by alimentary felt fabric. The fabric moves by 1 Motor – 0.5HP The cylinder is equipped with flour spray. The Divider equipped with control panel with on, off button The Divider equipped with Inverter to control the speed. The Divider equipped with safety sensors on the cutting knifes and flour spray And the control panel will control the first dividing proofer

Cooling Conveyers

After the bread out from the oven it moves on /50/meters, width /70/cm. made from Plastic until reach Packing room. Notes: Power 230 volt 3 Phase All sensors are made in Italy All the Motors in the line made in Turkey All production line is with safety covers for all stages The bearing is high quality European made The loaf diameter is (15 – 32) cm The production capacity is 5000 loaf / hour. The line is coated with Stainless Steel. The line matches the European rules for safety and health CE & ISO 9001

WSPT# LRGD-00000-033025-A

Picture 032625

NOTE: There will be a Rigging / Loading Charge for this item. Please inquire!

* All information deemed accurate but may vary from model to model.

Contact Larry for any questions you may have... GOOGLE "Larry Razza Machinery"

Contact us at Four Zero One - Nine Six Five - Five Five Five Seven

___________________________________________________

Equipment Financing Available, please contact us!

Fast Application, it’s all filled in for you...

Online leasing applications (get LOW monthly payments)

* Please Note: Not all machines may qualify for Leasing.

Payments: We accept all Major Credit Cards, Bank Wires, Company and Personal Checks.

SHIPPING: Contact us for great rates on shipping...

We always get better rates...

Please email us for a rigging and shipping quote; just include the zip code when inquiring and if you have a loading dock or ground level with forklift. Thank you!

Contact us at Four Zero One - Nine Six Five - Five Five Five Seven

We also ship worldwide.

CONDITIONS: All quotations are for immediate acceptance. They are subject to withdrawal, change and prior sale without notice. Shipping dates are only approximate and contingent upon delays beyond our control. All orders received are binding only when they have been accepted and acknowledged by us in writing. Provisions in customer’s purchase orders contrary to these conditions shall not be binding upon us unless accepted in writing. Unless otherwise specified, prices quoted are F.O.B. shipping point, exclusive of State, County and Federal taxes which must be added where applicable. Insurance on shipment must be requested by email, there will be an additional charge for shipping insurance. Shipping destination must be available to receive the shipment… any costs incurred on delays due to the buyers’ destination being unable to receive the shipment and/or additional services required, will be the responsibility of the buyer. Care is taken to give reliable specifications, but these are not guaranteed. We reserve the right to correct typographical errors. All used equipment is sold "as is".

INDEMNIFICATION: Used Machines may not incorporate approved activating mechanisms, operator safety devices or safety guards as required by OSHA or otherwise. It is the user's responsibility that the said machines be so equipped and safeguarded to meet OSHA and any other requirements before placing such machinery into operation. User agrees to indemnify and hold Seller harmless of and from any and all claims or liabilities from accidents involving these machines caused by failure of user, his employees, or agent to follow instructions, warnings, or recommendations furnished by manufacturer, or Seller, or by failure of user to comply with Federal, State and Local laws applicable to such equipment including the Occupational Safety and Health Act of 1970. User shall notify Seller promptly after occurrence of any accident involving these machines, and shall cooperate fully with Seller. or Seller's agent in investigating and determining the cause of said accident.

Specifications

| Manufacturer | ESO |

| Model | Egyptian Syrian Bread Making System |

| Condition | Used |

| Stock Number | LRGD-00000-033025-A |