Zenith 2018 AUTOMATIC ULTRASONIC Spotless Parts Washer & ULPA Dryer WATCH VIDEO!

Zenith 2018 AUTOMATIC ULTRASONIC Spotless Parts Washer & ULPA Dryer WATCH VIDEO!

$50,950 (USD)

Location:New Jersey

Description

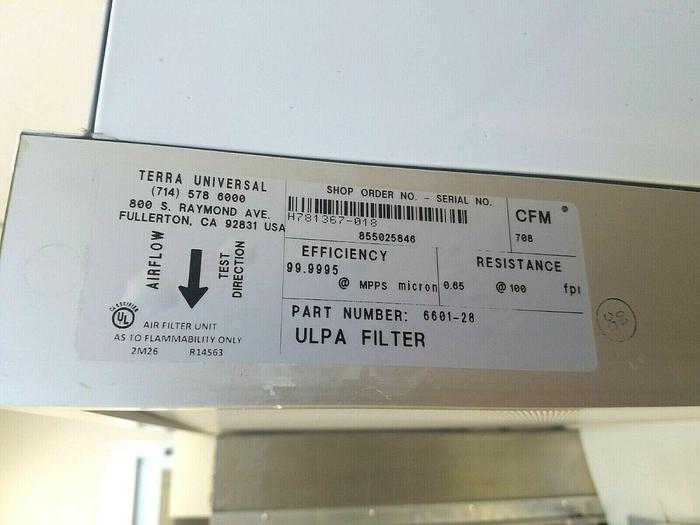

This is a Zenith 2018 AUTOMATIC ULTRASONIC Spotless Parts Washer with ULPA FILTERED DRYING!!! FAST SPOTLESS CLEANING OF Glass, Metal or Plastic Parts! MADE IN USA! WATCH VIDEO... Zenith Ultrasonic Cleaning System with ULPA Filtering offered by Larry Razza - YouTube... Video will open in a new window Using the eBay App? Paste link into a browser window: 4-tank Format Precision Series: Clean / Rinse / Rinse / Hot Air Dry ...for precision-grade zero-residue performance capabilities PLUS ULPA FILTER AIRFLOW OPTION FOR DUST FREE DRYING & D I WATER FILTERING SYSTEM. COST NEW WITH THESE OPTIONS OVER $180,000 ...VERY LITTLE USE ON THIS MACHINE! Zenith's newest automatic parts washer, the Advantage is the most ultrasonically-optimized automation system available and provides cleaning performance that cannot be matched by any other type of automation system. Anyone that knows anything about ultrasonic cleaners can tell you that the ultrasonic cleaning performance is directly related to the number of parts being cleaned, and the mass of the individual parts: The greater the number of parts being cleaned, the less ultrasonic energy that will be dedicated to an individual part. ANYTHING that is submerged in an ultrasonic bath absorbs some of the emitted energy, and changes the reflected patterns of energy in the tank To reduce the effect that the baskets have on ultrasonic cleaning performance, baskets are made just strong enough the support the batch of product with minimal mass to minimize energy loss and maximize cleaning performance. How ADVANTAGE Maximizes Ultrasonic Performance... The Advantage automatic parts washer uses Zenith's proven MBT transfer system to push baskets from tank to tank using a series of arms which are connected to a pneumatic cylinder or optically-encoded ball screw drive. This is identical to the way that our MBT system has functioned for decades. However, the Advantage system optimizes ultrasonic performance by: Eliminating any and all basket support structures under the parts. Removing basket supports allows all of the ultrasonic energy being emitted to be dedicated to parts cleaning. No structures under the basket which will absorb ultrasonic energy and change its reflected patterns in the tank. Each tank includes a dedicated oscillation platform that oscillates product during the process at a programmable rate to scan items through the standing waves of ultrasonic energy, remove loosened contaminants from detailed areas of the product, and prevent damage to sensitive components. Oscillation permits product to pass through the high-energy band just below the surface of the liquid. As the weight of parts becomes greater, support structures which would be included need to be more massive and thereby absorb even more ultrasonic energy. With Advantage, even the heaviest loads will not affect ultrasonic performance due to structural strengthening of basket supports. More information on the advantages of oscillation can be found in the Technical Info drop-down menu above under "Parts Oscillation". Test Results and Customer Feedback Foil tests which were performed in an ultrasonically-optimized system which supported baskets underneath vs. the Advantage parts washer design indicated that it took 10 times longer to produce 1/2 of the holes in the foil. In addition, holes in the foil were significantly more evenly distributed in the Advantage system. These easy-to-perform tests indicate that the Advantage design is at least 300-500% more ultrasonically effective than a system which suspends the basket from underneath. One customer who had an older system that supported the basket from underneath dropped his ultrasonic cleaning time from 10 minutes to 3 minutes, and felt that they could reduce the cleaning time even further and still get their parts clean. Another customer who had already decided to purchase their new system from a competitor whose machine supported the basket from underneath ended up purchasing multiple Advantage systems from Zenith instead after performing their own comparative foil tests at Zenith and its competitor. ADVANTAGE Automation System Features... All basket support structures are eliminated from the tank to maximize ultrasonic cleaning performance (patent pending) Baskets are pushed from tank to tank along a guided track Less possibility of system crashing due to falling baskets since baskets can never be disengaged from the support devices. Includes independent, programmable oscillation capabilities to every tank through the surface of the liquid to pass objects through high energy cleaning zones High load capacities are possible without reducing ultrasonic power in the tanks. Features which permit rotation of parts to permit even cleaning of parts with complex geometries. CROSSFIRE Multiple Frequency Ultrasonic Systems can be added to improve particle sizes most effectively removed and provide the cleaning properties of more-than-one frequency. NEMA4X control enclosures and color touch-screen operator interface with remote log-in and control capabilities. System input monitoring through the touchscreen display for easy troubleshooting. SSR-controlled Drying Tank for the most accurate temperature maintenance up to 250 degrees F. Multiple Recipe Processor allows each basket to be processed with different recipes of operation. Can be manufactured to utilize existing baskets. Light safety curtain for operator safety. Light signal tower with optional alarm horn alerts operators when needed. Large variety of options available to customize the system to suit your specific needs. Manufactured using readily-available components. All stainless steel construction with true tubular support frame. For a downloadable PDF Brochure see "Zenith Ultrasonics Advatage Model" 4-tank Format Precision Series: Clean/Rinse/Rinse/Dry for precision-grade zero-residue performance capabilities Specifications: Zenith Ultrasonics Advantage model Made In USA PLC Visual Touch Screen Process Controller MFG Date 2018 220V / 3 Phase / 60 Cycles Complete System Ulpa Filter (for removing dust while drying) D I Water Filter System SUPER HEAVY DUTY STAINLESS CONSTRUCTION We Finance... please contact us! Palm Tree Cat#LRMO-00000-0030920-A Picture# 030520 R051220DD Bid with Confidence on this item, check our feedback!!! * All information deemed accurate but may vary from model to model. Contact Larry for any questions you may have... Four Zero One - Nine Six Five - Five Five Five Seven or Contact us through EBAY Message Google "Larry Razza" for more information on our company. __________________________________________ Equipment Financing Available... Fast Application, it’s all filled in for you, please contact us! Online leasing applications (get LOW monthly payments) * Please Note: Not all machines may qualify for Leasing. Payments: We accept all Major Credit Cards, Bank Wires, Company and Personal Checks. SHIPPING: Contact us for great rates on shipping... We always get better rates... Please email us for a rigging and shipping quote; just include the zip code when inquiring and if you have a loading dock or if you are a residential delivery, Thanks! Contact us at Four Zero One - Nine Six Five - Five Five Five Seven or Contact us through EBAY Message We also ship worldwide. CONDITIONS: All quotations are for immediate acceptance. They are subject to withdrawal, change and prior sale without notice. Shipping dates are only approximate and contingent upon delays beyond our control. All orders received are binding only when they have been accepted and acknowledged by us in writing. Provisions in customer’s purchase orders contrary to these conditions shall not be binding upon us unless accepted in writing. Unless otherwise specified, prices quoted are F.O.B. shipping point, exclusive of State, County and Federal taxes which must be added where applicable. Insurance on shipment must be requested by email, there will be an additional charge for shipping insurance. Shipping destination must be available to receive the shipment… any costs incurred on delays due to the buyers’ destination being unable to receive the shipment and/or additional services required, will be the responsibility of the buyer. Care is taken to give reliable specifications, but these are not guaranteed. We reserve the right to correct typographical errors. All used equipment is sold "as is". INDEMNIFICATION: Used Machines may not incorporate approved activating mechanisms, operator safety devices or safety guards as required by OSHA or otherwise. It is the user's responsibility that the said machines be so equipped and safeguarded to meet OSHA and any other requirements before placing such machinery into operation. User agrees to indemnify and hold Seller harmless of and from any and all claims or liabilities from accidents involving these machines caused by failure of user, his employees, or agent to follow instructions, warnings, or recommendations furnished by manufacturer, or Seller, or by failure of user to comply with Federal, State and Local laws applicable to such equipment including the Occupational Safety and Health Act of 1970. User shall notify Seller promptly after occurrence of any accident involving these machines, and shall cooperate fully with Seller. or Seller's agent in investigating and determining the cause of said accident.

Specifications

| Manufacturer | Zenith |

| Condition | Used |